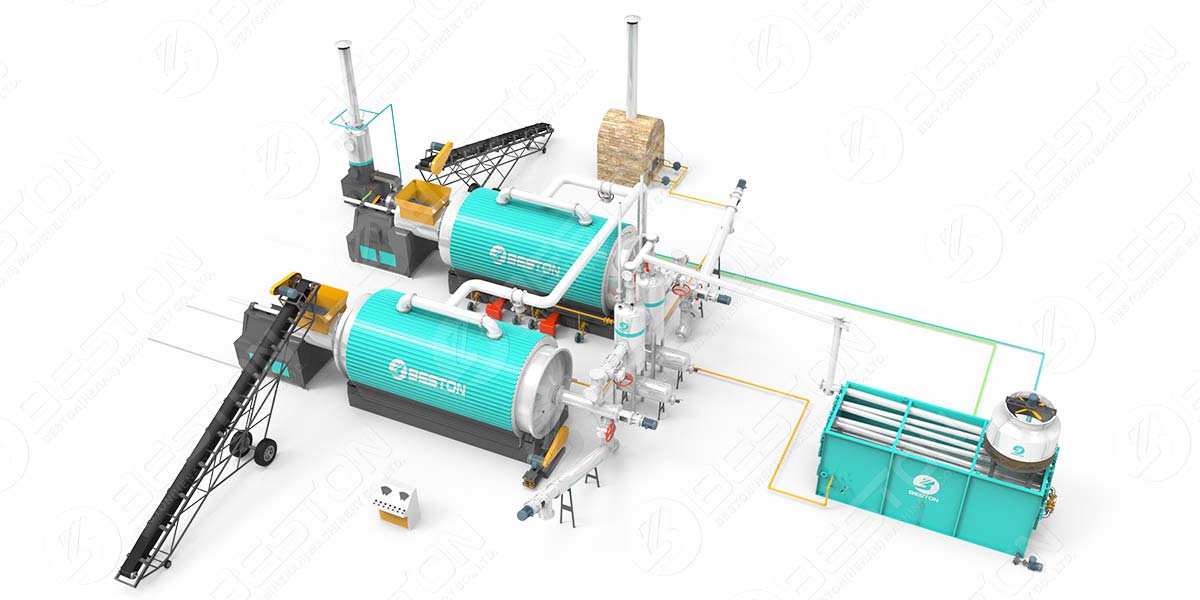

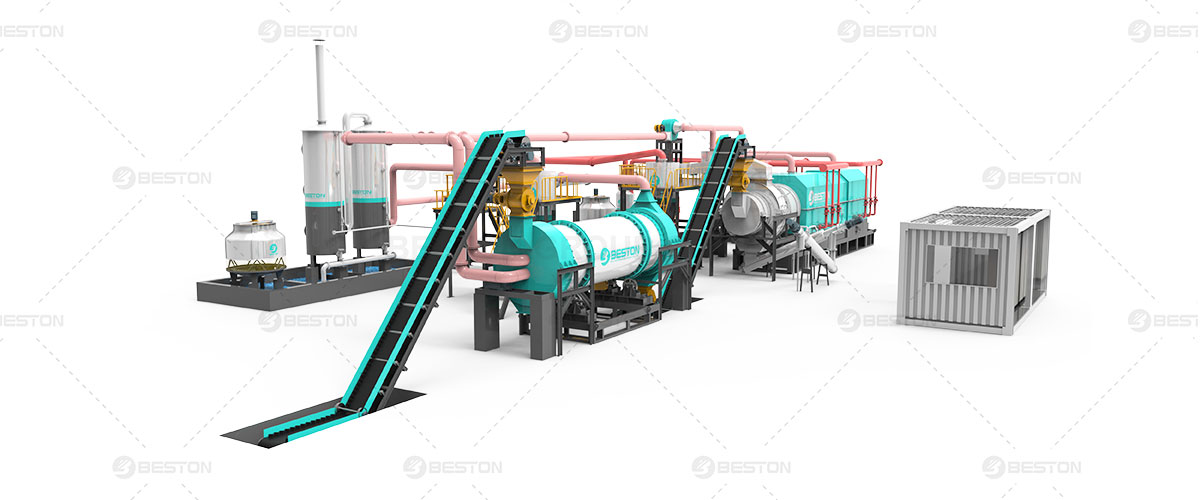

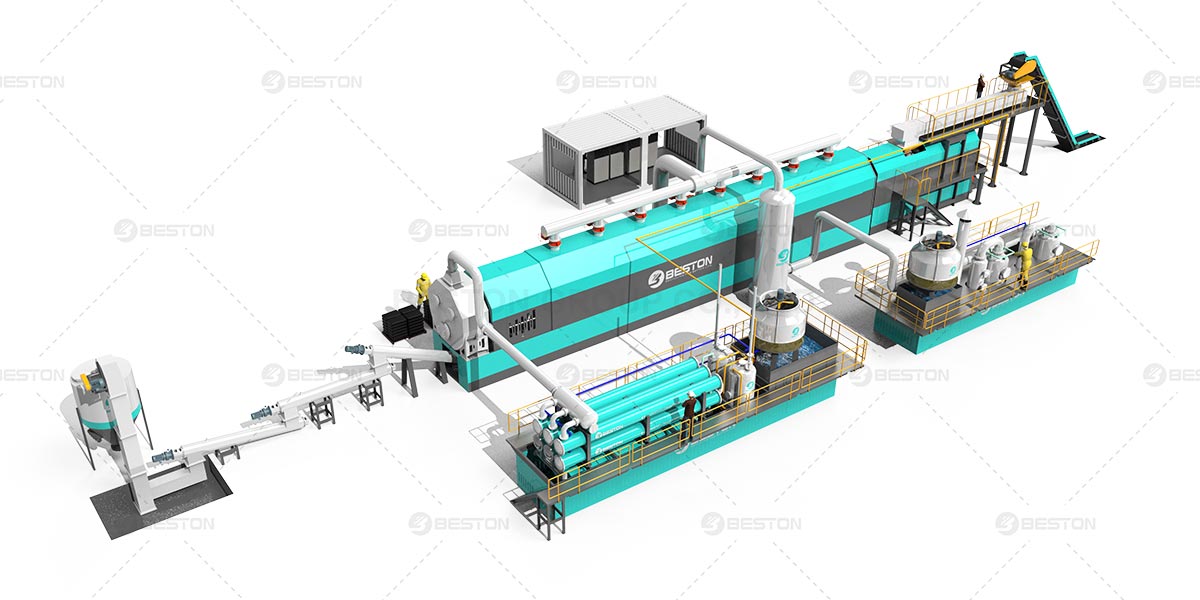

Biochar is a type of charcoal that is made from biomass, such as wood or agricultural waste. When used as a soil amendment, biochar can improve crop yields and reduce water and fertilizer requirements. Biochar also helps to improve soil fertility by increasing the retention of essential nutrients, such as nitrogen and phosphorus. In addition, it can improve soil structure and porosity, making it more effective at storing water and preventing erosion. As a result, biochar offers a number of benefits for sustainable agriculture practices. But what does the production equipment contain? Here are the essential parts of biochar production equipment:

1. Feeding System

The feeding system is responsible for delivering the raw material, typically biomass, into the reactor. There are various ways to achieve this, but the most common method is to use a screw feeder. The screw feeder consists of a large screw that rotates inside a tubular chamber. As the screw turns, it pushes the biomass forwards until it reaches the reactor. In some cases, the screw feeder may also be used to crush the biomass and mix it with other materials, such as water or air. This helps to ensure that the raw material is evenly distributed and correctly sized for the reactor. More information on charcoal making machine here.

2. Carbonizing System

The carbonizing system helps in heating the feedstock material to high temperatures in an oxygen-free environment. This process drives off moisture and volatiles, leaving behind a solid black carbon material. It usually consists of a stainless steel retort chamber, a combustion chamber, and a flue gas scrubber. The feedstock material is placed in the retort chamber, where it is heated by burning a fuel source such as wood chips or natural gas in a combustion chamber. The resulting flue gas is passed through the scrubber to remove any remaining particulates before being released into the atmosphere.

3. Discharging System

The discharging system moves the finished product from the reactor chamber to the collection area. There are two main types of discharging systems: manual and automatic. Manual systems require the operator to manually open and close a valve to control the flow of material. Automatic systems use sensors to monitor the level of material in the reactor chamber and automatically open and close the valve when the desired level is reached. See the biomass pyrolysis plant here.

4. Dedusting System

The dedusting system captures the emissions produced during the production process and prevents them from entering the atmosphere. It works by using a series of filters to capture the emissions. The first step is to collect the emissions in a dust collector. The dust collector contains a series of filters that trap the particles in the air. In the second step, the blower removes the captured particles from the dust collector. The blower sends a stream of air through the dust collector, which forces the particles out of the filter and into a collection chamber.

Biochar production is a great way to improve your soil while also sequestering carbon. If you’re looking for a way to reduce your environmental impact, biochar production may be the answer. Check the rice husk charcoal making machine here.