In continuous operations, particularly in industries that handle high temperatures and volatile substances, maintaining proper sealing is crucial for ensuring both efficiency and safety. For systems like pyrolysis plants, even the smallest leaks can lead to catastrophic failures. This article explores the importance of achieving reliable sealing in continuous equipment, specifically focusing on processes like pyrolysis plant operations, and how manufacturers prevent air leakage during crucial feed and discharge phases.

The Importance of Sealing in Continuous Equipment

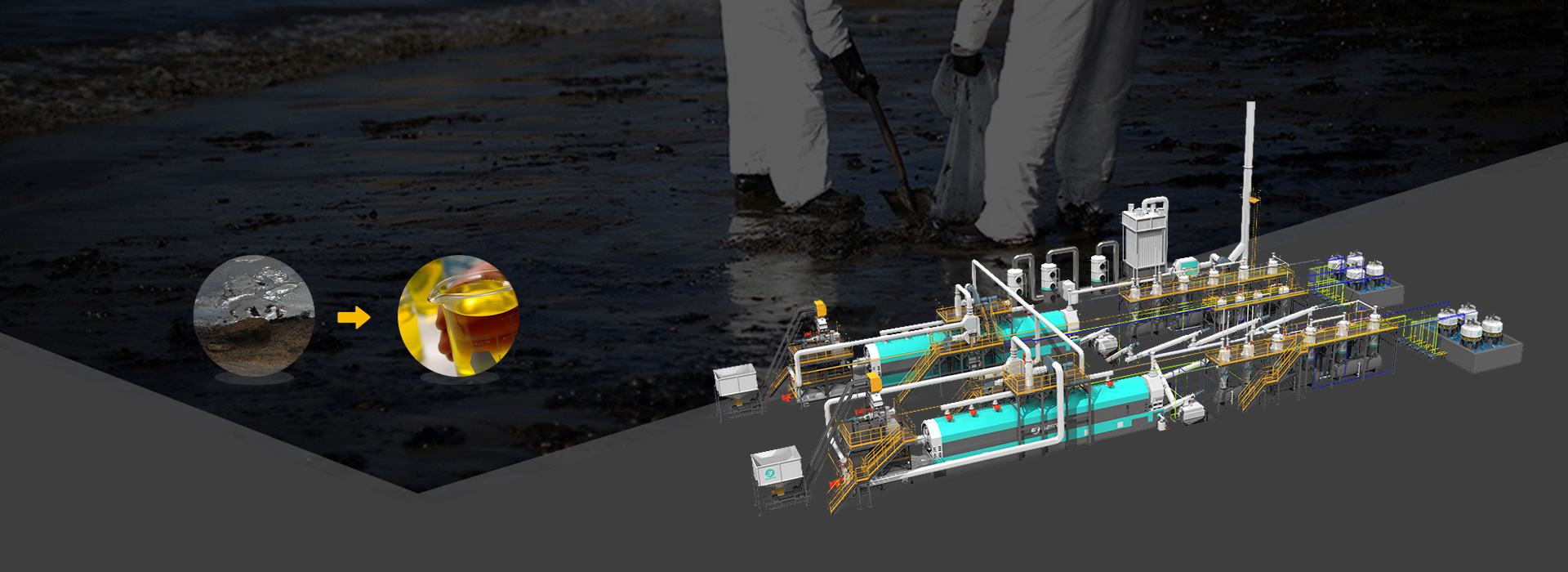

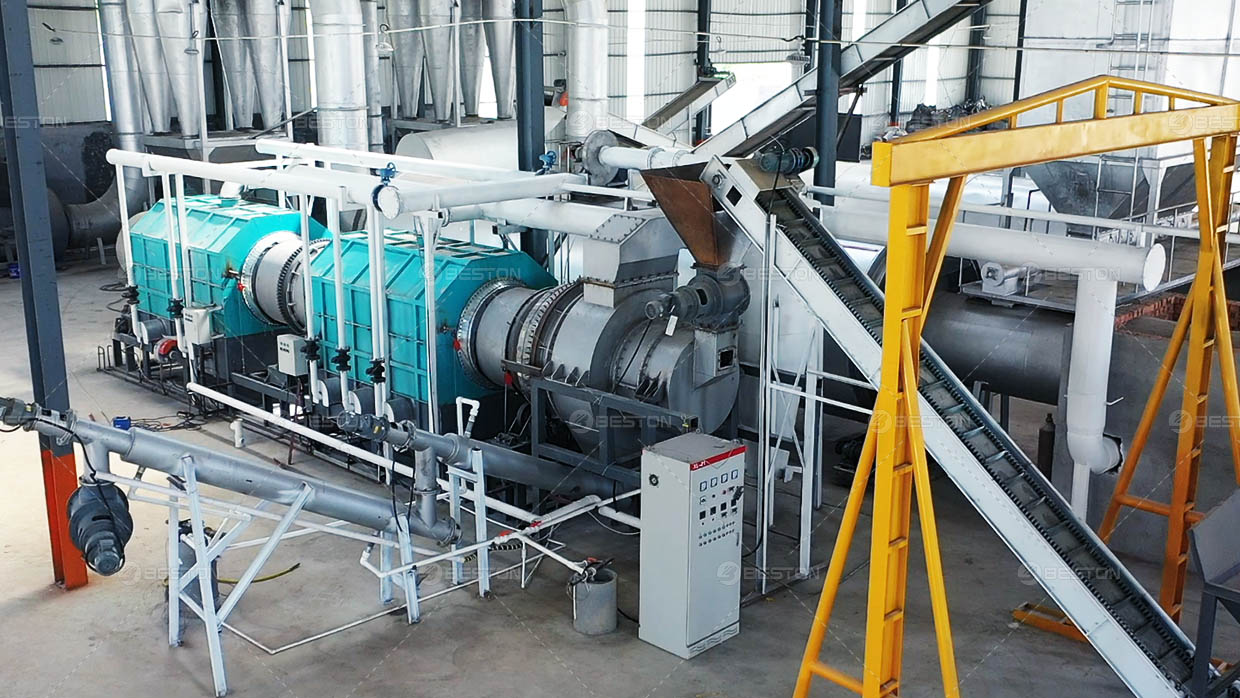

Continuous systems are designed for maximum productivity, and sealing plays a vital role in ensuring that they operate efficiently. Without a reliable sealing mechanism, materials inside the reactor, such as waste tyres, biomass, or plastic, could be exposed to outside contaminants, reducing the system’s overall efficiency. For example, in a tyre pyrolysis plant, where tires are continuously processed to produce valuable by-products, it is essential to ensure the system is airtight during both the feeding and discharging phases.

Challenges in Feeding and Discharge Without Leaking

One of the most common questions asked by users is, “How do you feed materials and discharge by-products without any leakage?” The answer lies in advanced sealing technologies that are built to withstand continuous operation. For instance, many continuous pyrolysis plant designs use specialized seals around the feed and discharge ports, ensuring that no gases or odors escape during the process. These seals must not only be resistant to high temperatures but also to the chemicals involved in the pyrolysis process. This prevents hazardous gases, including carbon monoxide, from leaking into the environment, ensuring safety and compliance with environmental regulations.

Sealing Materials: The Key to Longevity and Safety

The materials used for sealing are essential for ensuring long-term reliability. In many continuous systems, the seals are made from heat-resistant alloys or advanced synthetic rubbers that can handle the extreme conditions inside the reactor. These materials must be durable enough to withstand frequent thermal cycling without degrading. Furthermore, they must maintain flexibility to ensure that even under constant stress, the seals remain tight and prevent leakage. Beston Group has invested heavily in developing custom sealing solutions for pyrolysis systems, which is a key factor in the success of their operations.

Safety Measures to Prevent Gas Leaks

Besides the sealing technology itself, the safety systems that accompany these continuous operations also play a significant role. In many continuous pyrolysis plants, there are built-in gas monitoring systems that detect any potential leaks and trigger immediate shutdown or isolation procedures to prevent further issues. This ensures that any small issues are addressed before they escalate into dangerous situations. Regular maintenance and testing of these systems are also crucial in ensuring that the equipment remains leak-free throughout its lifespan.

Conclusion

In conclusion, the sealing and safety mechanisms in continuous operations are essential not only for maintaining high efficiency but also for ensuring the safety of workers and the environment. By investing in advanced sealing technologies and employing robust safety protocols, industries can ensure that their equipment operates smoothly without risking leaks. This is especially important in pyrolysis processes, where even the smallest leak can lead to significant safety and environmental hazards. Companies like Beston Group have demonstrated how proper sealing and continuous improvement of technologies lead to better performance and safety in industries like tyre pyrolysis and other thermal treatment processes.