The egg tray machine for sale South Africa is one of the best machines for recycling wastes. This machine can be used for making paper egg trays with paper or agricultural wastes. Plus, the low cost of the machine makes it really popular among small investors. You can also find high-end production oriented machines as well. But the burning questions are – Will the plant give better profitability and is it worth your investment?

Let’s analyze it in a nutshell before we take on the viability of the venture comprehensively. Firstly, the machine seems to be a better alternative to replace plastic egg trays that are actually harmful to the environment. Secondly, the machine uses paper wastes in the recycling process.

Now let’s get familiar with the process of making egg trays and assess the viability of the venture to ascertain whether it’s worth investing.

How to Make Egg Tray From Waste Paper?

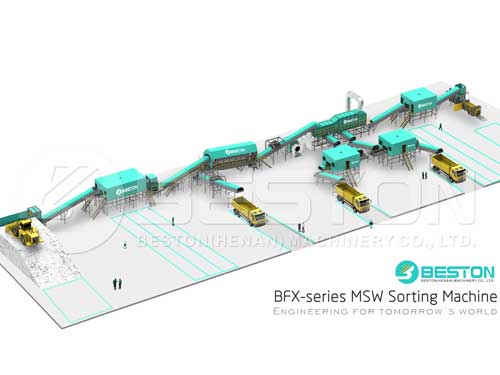

Making paper trays from waste is simple with this modern recycling plant. To start with, waste paper and sugarcane bagasse are dumped into the machine through a feeder system. Here, the materials are moved through the drying system to remove moisture from the raw materials.

After removing moisture, materials are stirred, smashed, and filtered to make a fine smooth pulp through a pulp making machine. After pulping, the materials are passed through a pulp molding equipment where the egg trays get their shape. Finally, the trays are dried and packed. From the packing area, the trays are dispatched to various markets as per demand.

Is Egg Tray Machine Worth the Investment?

As a businessman, you may want to ascertain whether the venture you’re considering is viable and whether it will deliver profitability. Also, you may want to work out the cost-benefit ratio and other parameters before taking this venture seriously. So, let’s examine all such points to calculate the feasibility and viability of this waste recycling plant.

Cost-benefit ratio

Some businesses think that the project requires too much capital and space area. However, these myths are far from the truth. The reality is the machine is investment-friendly. With a modest capital, you can buy the plant. If you’re still low on investment, you can choose a manually operated machine or a semi-automatic machine.

As far as space is concerned, the machine takes up very little area. You can rent or buy a small factory (as you like) and start the production process. If you compare the space area and capital required for this innovative recycling plant with other waste recycling machines, you’ll find that the egg tray machine requires comparatively less capital and space area. At the same time, the benefits are limitless in terms of high production and low investment.

Labor cost

Most of the machines need too much labor. You need some operators to run the machine. Also, you need workers to sort the end products. However, the egg tray machine from Beston Machinery needs less labor. With a few workers, you can start your production cycle. Moreover, Beston waste recycling unit is also praised for its safety and ecofriendliness.

Production cost

All heavy duty plants are not alike. Some plants increase the cost of production. However, the Beston’s egg tray machine lowers your production costs in many respects. Firstly, the machine gives higher output. Plus, the plant needs fewer workers. Above all, the plant doesn’t consume too much energy. If you calculate all these things, you’ll come to the conclusion that the cost of production of egg trays is pretty low.

Availability of spare parts

When you run an egg tray manufacturing unit, you’ve to buy spare parts in order to keep the machine running efficiently. Some parts of the machine are bound to sustain damages and wear out over time. If the parts are costly, it can hurt your normal working capital as well as profitability. However, Beston’s egg tray machines are made with cost-effective parts. Also, the parts are easily available in the market.

Downtime check

Downtime is common in any manufacturing unit. Any plant stops functioning and needs overhauling periodically. That can affect your production cycle and profitability to a large extent. However, the egg tray machine from Beston has minimum downtime. Consequently, your production cycle goes on smoothly without any hindrances. Minimum downtime also assures that you can meet the requirements of your customers without any time-lags.

Finishing Words

Investing in the egg tray machine for sale South Africa is highly recommended for any businessman. Your reasonable investment will yield higher profits over and over. In simple words, you may conclude that investing in Beston’s paper egg tray machine is really worth every penny.