Charcoal kilns are an important part of the charcoal manufacturing process. These days, they are mostly automated, but charcoal kilns have been around for hundreds, if not thousands, of years.

Of course, if you are considering purchasing a charcoal kiln for your own operation, you probably want to know a little about the price. You may also want to know where you can find such a kiln and what is the best option for finding a charcoal kiln for sale.

Although some people may still want to manufacture charcoal in a traditional kiln, there are actually many different options on the market today that can get you up and running in a more automated fashion. These kilns offer many different options, but perhaps the most important option to consider is the price.

Some of the smaller biochar reactor for sale you will find for sale may be available for just a few thousand dollars. If you are looking for a higher-end charcoal kiln that can manufacture a lot of charcoal every day, then you could easily spend $10,000, $20,000, or more.

Aside from the price, where can you find these items on sale? Perhaps the most common place to purchase a charcoal kiln is through a wholesale service, such as Alibaba.

At times, companies may be selling these through a broker as well. This is not as likely to be the case, but you can run across the deal on occasion as some companies are upgrading their service to have a more expensive kiln on hand.

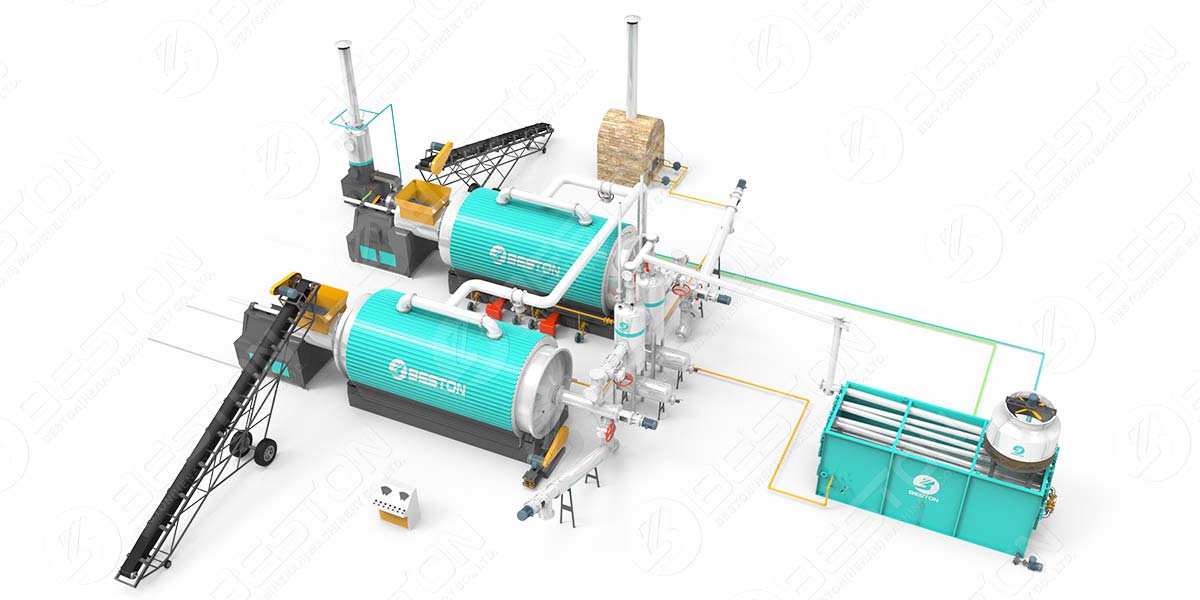

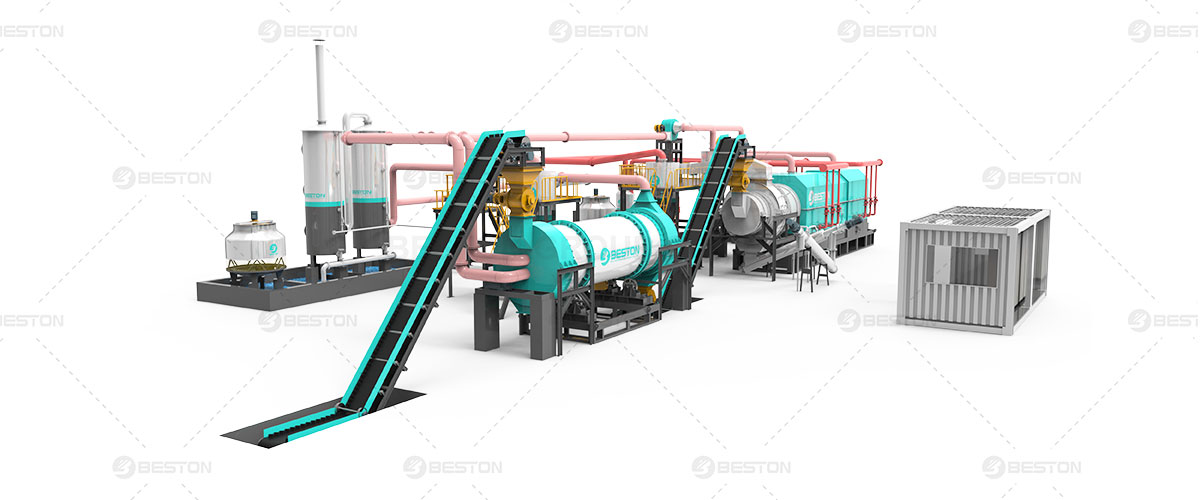

Another thing to consider is the options. Some of the charcoal making machine prices are part of a complete kit that will help you to make the wood charcoal briquettes out of raw material. This is an excellent option, as it can get your business up and running with only a single piece of equipment.

You may also find some continuous carbonization furnaces that turn the raw material into charcoal logs. Some of these are perfect for large operations, and you can expect to spend as much as $80,000 or more for such a machine.

Choosing a charcoal kiln that makes use of different types of raw materials is a good option. If you are trying to make your business stand out, then using something such as a coconut husk is a good selling point.

The ease of use is also something to consider. In some cases, it’s just a matter of opening the door, stacking the wood on the inside, making sure it is even, and then sealing the furnace before firing it up. After the charcoal is made and cooled, it is ready to pull out and use: https://bestonasia.com/mobile-biochar-machine/.

In the end, it really depends on why you are looking for a charcoal kiln for sale. If you need it as part of a larger process, you may find that purchasing a dedicated kiln is the best option for you and your business.

On the other hand, you can purchase an all-in-one piece of equipment that includes the kiln and everything else necessary to make everything from wood pellets to barbecue briquettes.