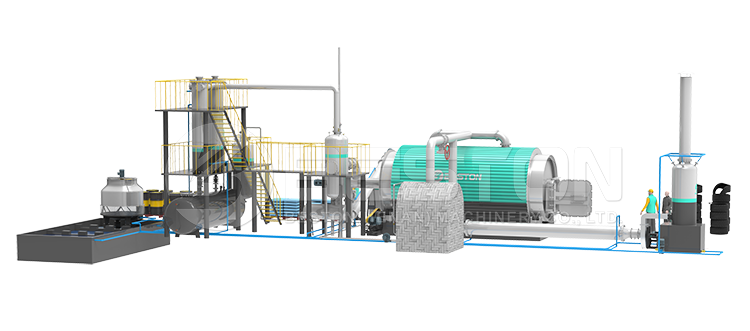

Any type of industrial facility is going to have project reports that are made on a daily basis. Commercial facilities, as well as small businesses, are going to monitor what is happening. This allows them to understand how the company is running. It also provides them with the feedback necessary to make necessary changes. These reports are also useful when you are working with different types of machines, or entire plants that are designed to produce materials. If you own a tyre pyrolysis plant, it is likely that you will be producing project reports continually. This is what you can expect in those project reports and how they will help you with your tyre pyrolysis plant production levels.

What Does The Report Present?

These reports will present a wide variety of information. It may begin with how much input material was used and what the output was at the end of the day. This is a good way of gauging the efficiency levels of the pyrolysis reactor. Likewise, you can see how many people were working to maintain the entire system. These factors, along with how much electricity is used to run a pyrolysis plant, can help you see what the bottom line is. The goal of any business is to spend less money on their business and make more profit. These reports will provide that information. If you want a customized tyre pyrolysis plant project report, check the link here: https://ecobeston.com/tyre-pyrolysis-plant-project-report/.

How Is The Information Gathered?

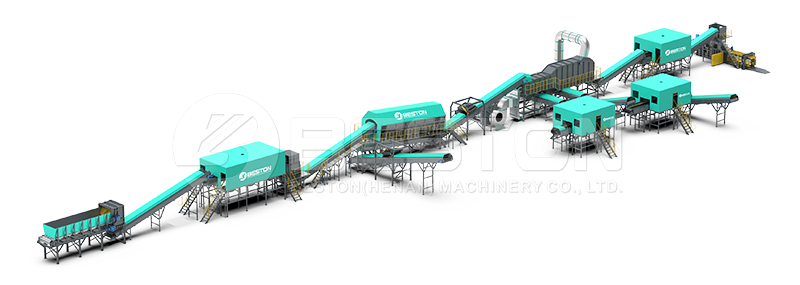

Information for these reports is gathered by doing a couple of different things. First of all, each individual employee will be responsible for one department. These reports are then correlated into a single report which provides information at each part of the process. For example, you would have reported on how much material was going in each hour. There would be reports on the total amount of fuel that was produced. There may also be reports on how much time the pyrolysis reactor was operating per day. This information is helpful when trying to plan out a course of action to improve overall production.

Do All Pyrolysis Plants Need Project Reports?

Since these reports are designed to provide daily feedback, it is very important for every pyrolysis plant to have this type of feedback level. Small adjustments can be made where necessary to improve the efficiency of these units. Over time, this can be refined, leading to the perfect way of producing fuel from charcoal. The cost of these plants may also factor into what the project report is going to say. If you have multiple pyrolysis reactors, your efficiency levels will be higher, yet there is also much more to monitor for each report.

Even if you have a small business, you need to have the feedback that these reports can provide. It allows you or workers to track what is working and what should not be utilized at all. It is going to take just a few minutes to go over the reports daily. This information can help a business become more efficient and profitable, regardless of its overall size. If you want more details, you can contact Beston Machinery for help. Below is the website for you: https://ecobeston.com/.