There are different types of energy that can be used by countries worldwide. This would include coal, oil, and gas. What is interesting is that more countries than ever before are beginning to utilize more organic resources. There are many waste products, especially in the organic industry, for example, coconut shells, sawdust, etc. In some cases, this material is earned or discarded. However, savvy inventors have created ways of utilizing this waste and converting it into charcoal. This is exactly what a biochar making machine is able to do for many businesses around the world.

What Is Biochar Production Technology?

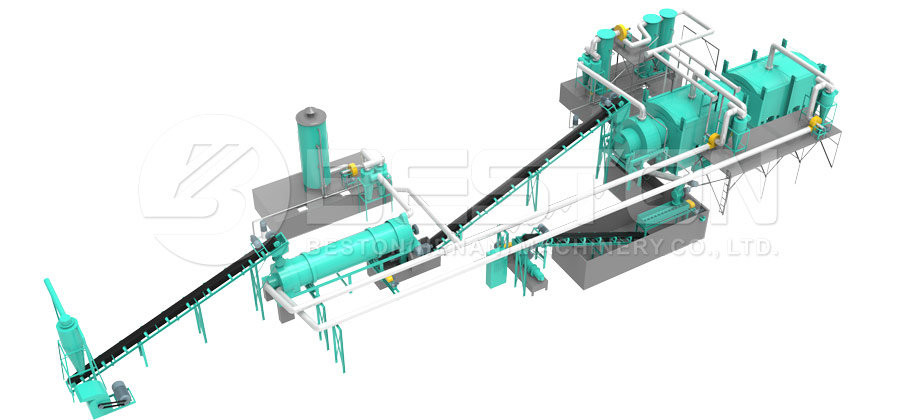

This is a type of technology that can really improve the way that we use fuel today. For example, you can put different materials such as tree branches, bamboo, sawdust, and even coconut shells into these machines and it will produce a burnable byproduct. The same can be said for the pyrolysis machine that can convert plastic or rubber into fuel oil. However, there are biomass pyrolysis machines that specifically work with organic materials. This could be sewage sludge, or materials that are similar, which can be carbonized and made into charcoal. More models of biomass pyrolysis equipment can be found: https://wasterecyclingplant.com/biomass-pyrolysis-plant/.

Why Is This Technology So Important?

This carbonization technology is important because of everything that it can provide. For example, you may not realize how easy it is to mass thousands of tons of material over the course of one harvest. You may have all of the seeds that need to be processed or the residue from rice. All of this can be placed into a charcoal furnace and converted into charcoal. There are many byproducts which will include both solid and liquid materials. They can burn just as well as the coal and gasoline that we produced today. It just requires a few modifications to improve its overall efficiency. Below is a video for your reference.

Is This the Movement Of the Future?

Charcoal making machine is certainly the wave of the future. More businesses than ever before are going to focus on this type of technology. It will not just be farmers, or individuals that are growing materials. This could be municipal solid waste factories where this type of waste in large cities, and small communities, is processed. Once this is done, this will improve upon the way we conserve fuel in the world and also help businesses save and make more money. Without this technology, it is likely that we would be on a path that would lead to higher fuel costs.

Fortunately, there are many individuals and companies working toward making biochar production technology readily available. This may be something that the average person can use, but for now, it is used by small and large companies. If you do have a farm, or if you have an MSW recycling facility, contact someone about this outstanding technology that is soon becoming one of the most viable solutions for energy that we need. Here is a website for you: https://wasterecyclingplant.com/.