Paper recycling is one of the best ways to convert wastes into usable products. Paper recycling has greater benefits, not only in the environments and society but also on the economy. One of the best ways of recycling paper is to convert waste papers into egg trays or egg cartons. That’s why paper egg tray machinery is getting popular. Egg carton machine is developed on the basis of egg tray machine, and it is a kind of pulp molding machine.

Advantages of Pulp Molding Equipment

Here are some of the top benefits of recycling waste paper into pulp molded trays:

1. Pulp moulding machine is eco-friendly. And it helps to prevent pollution.

2. Since this process prevents waste of paper, it is cost-effective.

3. It helps to keep the environment clean and preserves the anaesthetic image.

4. The process provides job opportunities.

5. It promotes efficiency by reducing the amount of waste paper turnout from companies.

Egg Carton Manufacturing Process

An egg tray making machine for sale is used for manufacturing egg trays from waste paper. It is the most common pulp molding machine that is used globally for paper recycling.

The egg tray manufacturing process involves four major stages:

1. Pulping System

This is an important part of the egg carton manufacturing process. The pulping system converts waste paper into pulp. The hydraulic pulper in the system smashes the waste paper into the pulp while stirring and rubbing at the same time. The pulper also filter the paper. Beston Machinery’s pulping system comes with a refiner to make the pulp smoother and well-partitioned. In addition, they offer an integrated pulping system that can efficiently save you more production and construction efforts, and space.

2. Molding System

This section of the paper egg tray machine is the core part. It contains a pulp molding machine, which is the key equipment integrated with a vacuum pump and an air compressor. The molding machine molds the pulp into the trays, boxes or cartons while the vacuum pump helps the molding process. The air compressor is used for transferring the wet products out of the molds. Many pulp molding systems don’t come with cleaning devices, but Beston Machinery’s fully automatic egg tray making machine comes with complete, automated and easy-to-operate cleaning devices.

3. Drying System

Drying system is used to dry the wet products. There are different drying systems with different drying lines. The most important aspect of a drying system is the heat recycling modality. As regards Beston Machinery, a professional egg tray machine manufacturers in China, they offer professional designers to provide you with an effective drying line for efficient recycling of heat. This will save your energy and fuel usage, as well as the cost of fuelling the system.

4. Packaging System

The packaging system entails packing and counting. For better appearance and quality of the end products, Beston Machinery egg tray making machine comes with hot press technology to reshape the egg trays.

Ultimately, in order to provide for the customers’ needs and requirements worldwide, Beston Machinery supplies manual, semi-automatic egg tray machine, and fully automated egg tray machine types. The company is located in China with their supplies and main markets in the Philippines, South Africa, Indonesia, Romania, and Thailand.

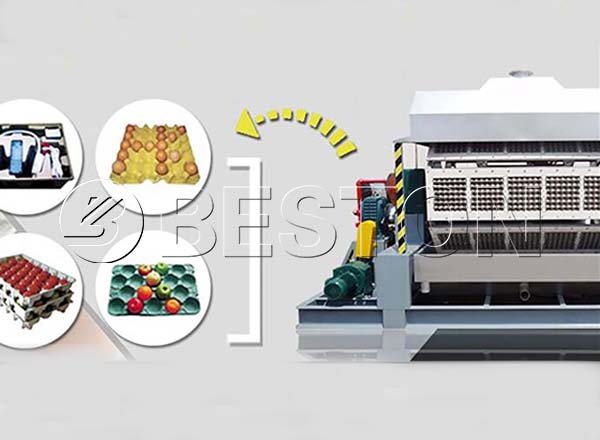

One of the rare benefits of Beston Machinery’s egg tray machine is that it comes with different moulding dies that are not only useful for manufacturing egg trays but also useful for manufacturing egg cartons/boxes, fruit trays and much more. Furthermore, the egg carton manufacturing process of the machines is impeccable. Welcome to contact Beston for more details. Also, you can check Beston Youtube Channel for more videos.