Biochar production life cycle analysis (LCA) is an essential framework for evaluating the environmental and economic impacts associated with the production and application of biochar. This process scrutinizes each stage of the biochar production chain, from raw material acquisition to end-use applications. By utilizing a life cycle approach, stakeholders can assess the sustainability of biochar systems, identify improvement areas, and measure the potential environmental benefits, including carbon sequestration and soil health enhancement.

Key Stages in the Biochar Production Life Cycle

The life cycle analysis of biochar production can be broken down into several distinct stages. Each stage holds significance in determining the overall environmental impact of the process, particularly in relation to greenhouse gas emissions, energy consumption, and resource use.

1. Feedstock Sourcing

The first stage involves the acquisition of biomass, the raw material used in biochar production. Biochar production equipment relies on various biomass sources, including agricultural waste, forestry residues, and organic matter from municipal solid waste. The sustainability of feedstock is critical, as the type and source of biomass can influence the net carbon balance. For example, using waste biomass or residue materials can lead to lower environmental impacts, while dedicated biomass crops may involve higher land and water use.

2. Pyrolysis Process

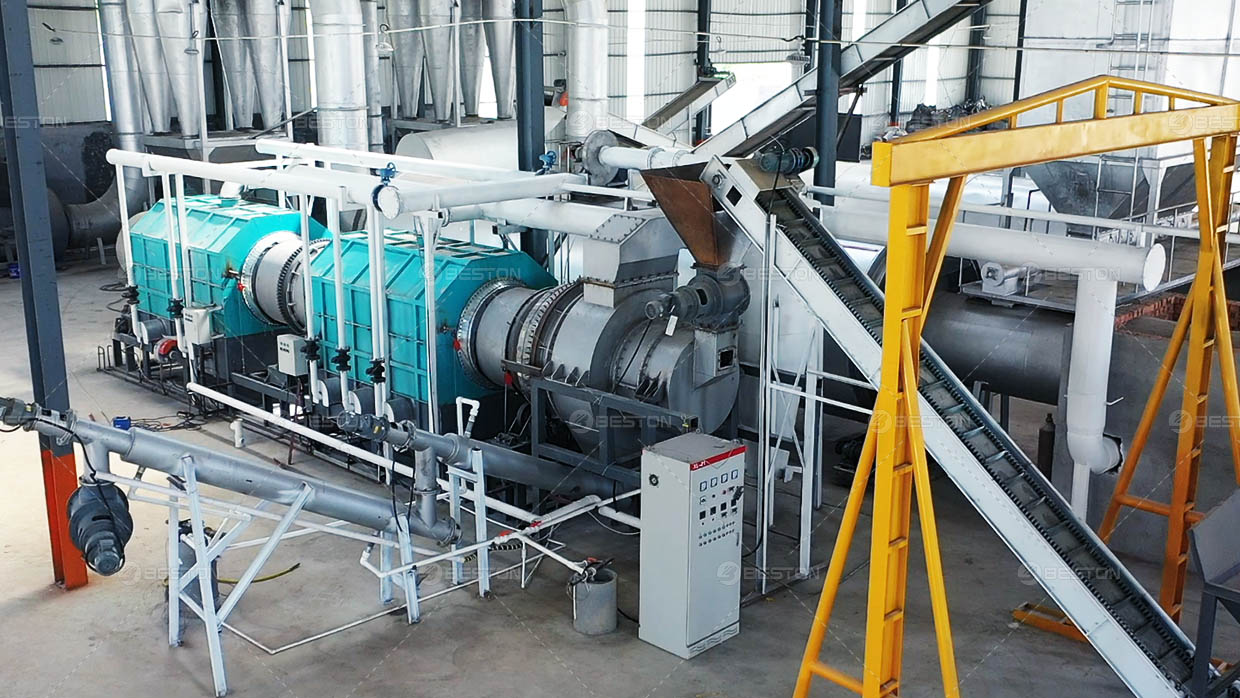

The core of biochar production lies in the pyrolysis process, where biomass is thermally decomposed in the absence of oxygen to produce biochar, syngas, and bio-oil. The efficiency of the pyrolysis technology significantly affects the life cycle impact. Advanced biochar production equipment often features continuous operation systems that improve energy efficiency and optimize yield ratios. During pyrolysis, the energy input and the emissions generated, including methane and carbon dioxide, are crucial factors in determining the overall sustainability of the biochar production process.

3. Energy Recovery and Co-Products

Another important element of the biochar production life cycle is the energy recovery from syngas and bio-oil, byproducts of the pyrolysis process. These co-products can be combusted for energy generation, reducing the need for external energy inputs. This stage enhances the overall energy balance of the production system. Furthermore, advanced biochar production equipment allows for the effective capture and utilization of these byproducts, contributing to a more circular production model and minimizing waste.

4. Transportation

Transportation plays a role in the LCA by determining how biochar and its feedstock are moved between different stages. The distance between the biomass source, production facility, and application sites can influence fuel consumption and associated emissions. Utilizing local biomass sources and optimizing transportation logistics is a key strategy in reducing the life cycle impact of biochar production.

5. Biochar Application

The final stage in the life cycle is the application of biochar to soil. Biochar is known for its ability to sequester carbon, improve soil structure, and enhance water retention. However, the benefits largely depend on the specific type of biochar produced, the soil characteristics, and the manner in which the biochar is applied. In an LCA, this stage considers the potential for long-term carbon storage and soil productivity, as well as any emissions related to the distribution and application of biochar in agricultural systems.

Environmental Benefits of Biochar Production

Biochar production, when optimized, offers substantial environmental benefits. Among the most notable advantages is carbon sequestration. During pyrolysis, a significant portion of the carbon present in the biomass is captured and stored in the biochar itself, rather than being released into the atmosphere as carbon dioxide. This stored carbon can remain stable in soils for centuries, making biochar an effective tool in mitigating climate change.

Another key environmental benefit is the enhancement of soil fertility. Biochar improves soil structure, increases nutrient retention, and enhances microbial activity. These factors contribute to improved agricultural productivity, reducing the need for chemical fertilizers and irrigation. Additionally, biochar pyrolysis equipment designed for energy recovery further enhances environmental performance by converting waste biomass into renewable energy.

Economic Considerations in Biochar Life Cycle Analysis

While the environmental benefits are clear, the economic feasibility of biochar production is another critical factor examined in the life cycle analysis. The capital cost of biochar production equipment, operational costs, and the market demand for biochar and its byproducts are central to determining the economic sustainability of the process.

Capital and Operating Costs

Biochar production equipment can range from small-scale systems suitable for local operations to industrial-sized units designed for continuous production. The capital investment required for these systems varies significantly depending on scale, technology sophistication, and production capacity. In addition to the upfront cost, operational expenses such as labor, energy, and maintenance must be factored into the life cycle analysis. High-efficiency equipment, although more expensive initially, often results in lower long-term operational costs due to improved energy use and reduced waste.

Market Demand and Revenue Streams

The market demand for biochar has been steadily increasing, particularly in sectors focused on sustainable agriculture, waste management, and carbon sequestration projects. Biochar carbonization equipment that efficiently converts waste biomass into high-quality biochar offers multiple revenue streams. In addition to selling biochar as a soil amendment, businesses can also capitalize on the energy generated from syngas and bio-oil, contributing to overall profitability.

Policy and Incentives

In many regions, biochar production is supported by government incentives and policies aimed at reducing carbon emissions and promoting renewable energy. These programs can enhance the economic viability of biochar production by providing subsidies or tax credits. Including these incentives in the life cycle analysis helps provide a more comprehensive picture of the financial sustainability of biochar production systems.

Conclusion

The life cycle analysis of biochar production offers a detailed perspective on the environmental and economic impacts of this technology. From feedstock sourcing to biochar application, each stage of the process plays a vital role in determining sustainability. By utilizing advanced biochar production equipment, optimizing energy recovery, and reducing emissions, biochar systems can offer significant contributions to climate change mitigation, soil enhancement, and waste reduction. Through careful evaluation of both environmental and economic factors, biochar production has the potential to become an integral part of sustainable development strategies across various industries. For sustainable biochar production options please contact Beston Group.