There are various types of equipment that are needed by businesses that sell fragile items. One of those is a molded pulp packaging machine. Also referred to as a paper pulp production machine, these are available in many different sizes. You should be able to obtain one that can save you a considerable amount of money. The pulp is produced first, and subsequently it is inserted into molds that will lead to packaging products that you can use for your business. Instead of obtaining these from a third-party which can be very expensive, you can obtain this molded pulp packaging machinery for less.

What These Machines Are Capable Of Doing

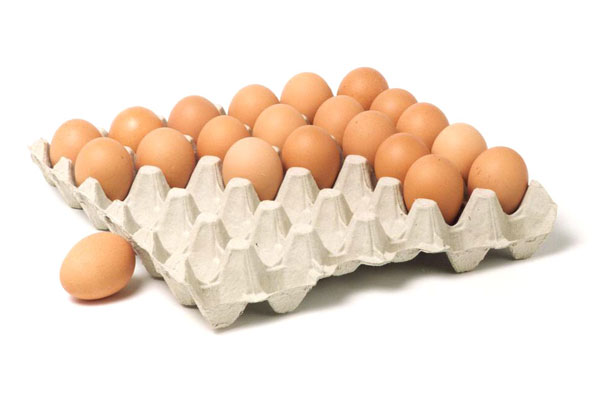

The basic functionality of these units is to produce paper mold products that can be used for shipping. As you are preparing for summer, you can quickly find a business that can help you. They can offer you an exceptional deal on some of their latest units. These paper tray making machines are capable of producing virtually any kind of paper mold product. This will include materials for shoes, electronic devices, and many others. In terms of obtaining one for your farm if you have millions of eggs that are produced, this is a great way to get started.

What Businesses Would Need This Type Of Product?

The businesses that will use these machines most effectively will include those that sell products like eggs. If you have ever seen eggs at a grocery store, they are in packaging made from paper pulp. These machines are capable of producing these materials. When you are in package an electronic device, or if you have ever purchased choose from the store, you have seen the types of products these machines can produce. Molded pulp packaging material can be vital to the success of your business. It just takes a little bit of time to find the best company to work with before making your purchase: https://pulpmouldingmachines.com/egg-tray-manufacturing-machine/.

How To Find These Molded Pulp Packaging Machines

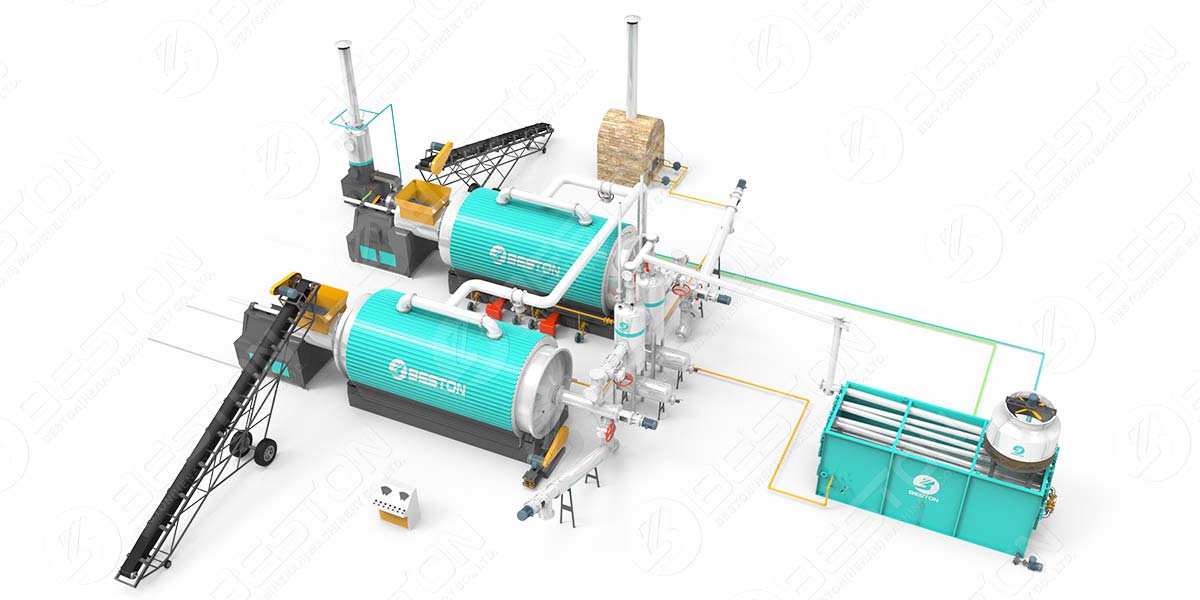

Machines that are produced by these companies are numerous. You should be able to locate the packaging production machinery that you need for your company fast. These are businesses that specialize in the creation of different types of molds and materials that can suddenly produce packaging paper pulp products that you can use. Some are very elaborate systems that are often found at factories. However, you can also get pulp molding machine that is much smaller. All it takes is a small amount of time to obtain the one that you will require for your business. Consider the output capacity of these machines as well as the total price you will pay.

Molded pulp packaging machinery is available in most countries. When you shop outside of your own nation, you may find exceptional deals. The cost of production, as well as the total cost of labor would making these machines, can be quite minimal in certain countries. Obtaining quotes from different businesses will help you see what the price range will be. You may want to choose something that is in the middle. Overall, the possibility of saving money with your business that uses molded pulp packaging is certainly high when you consider how many businesses are producing them.