Most people think that rice husk has no use and they usually burn it off. However, it can be converted into charcoal. There are two ways to do it.

One of the ways is to pack the husk in briquettes and carbonize it to turn it into charcoal. The other method is to first convert rice husk into powdered charcoal and then pack it in briquettes. If you are doing it at small scale, you can probably do it manually as charcoal making isn’t a newly discovered technology. It has existed for hundreds or probably, thousands of years.

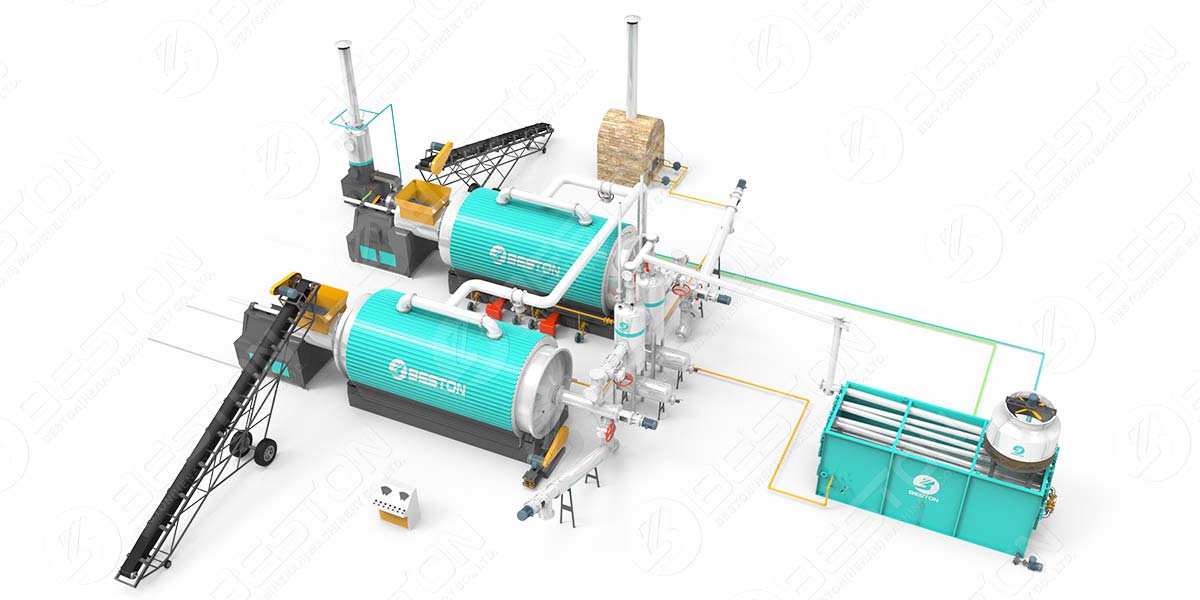

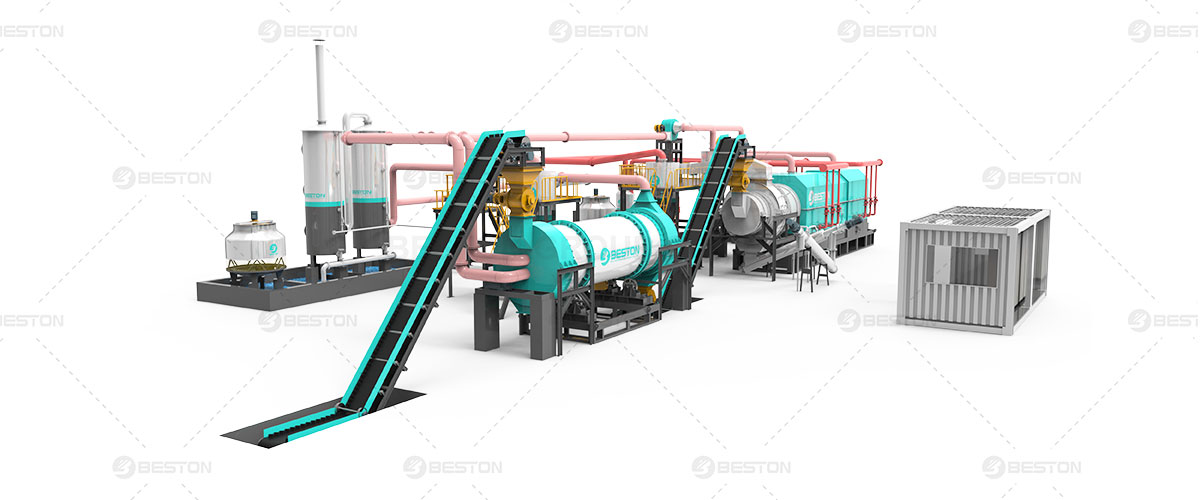

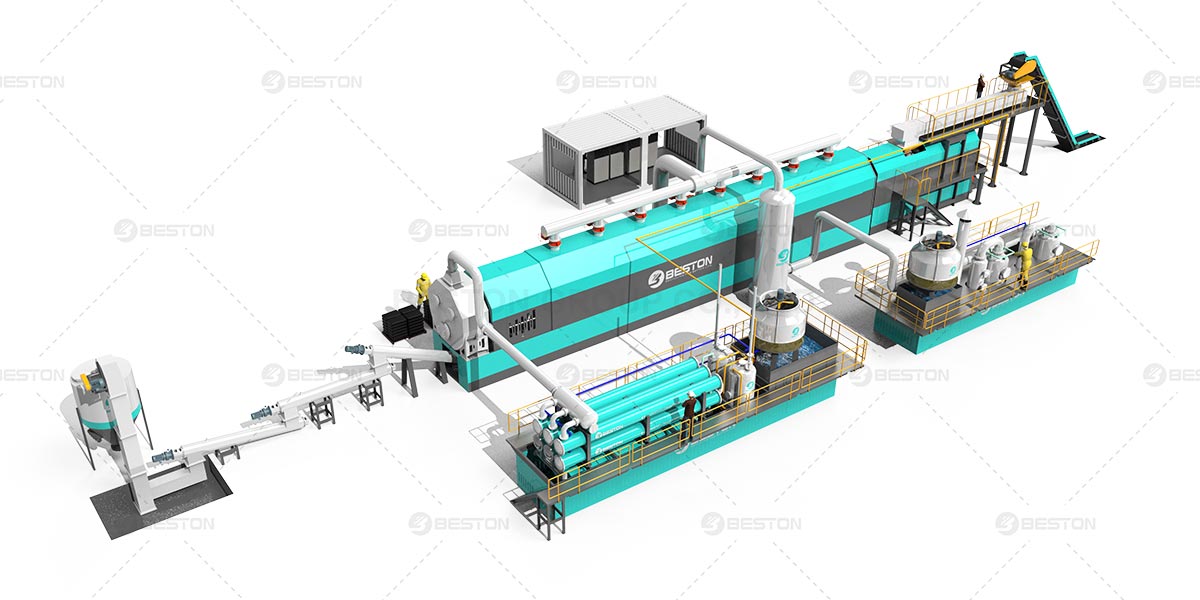

However, doing it at commercial scale is a different ballgame. You will need a proper rice husk charcoal making machine to make charcoal from rice husk at scale.

How to Buy the Right Machine?

A simple search on Google for this machine will return millions of results. However, you can’t buy it from any manufacturer and expect great results. In this section, we will cover important factors that matter in the long run when buying this machine.

Quality of Components

The most important thing that is going to affect the quality of charcoal is the quality of components used in the biomass carbonization machine. Components made from low quality materials won’t last long and may also affect the quality of charcoal obtained from the process.

Design of Machine

Pay special attention to the design of the machine. It should be easy to operate and easy to clean. If you want to obtain the maximum yield from this machine, you need to clean it properly after every batch.

If it is difficult to clean, you will obviously find it hard to clean it every time you make charcoal and that is going to affect derived yield and efficiency.

Fuel and Yield Efficiency

You’re obviously going to burn fuel to make charcoal from rice husk. Some machines are much better designed in terms of fuel consumption. Also, these machines are capable of burning a wide range of fuel.

On the other hand, there are also machines that have poor fuel efficiency and are limited to only a few types of fuels.

Brand

It makes sense to pay premium for a reputed brand. Reputed brands have their reputation at stake and they have proper quality control processes to ensure that every single piece that beers their name conforms to certain standards. Stay away from no-name brands as it is unlikely that they will last as long as the products from a reputed brand: https://bestonasia.com/charcoal-making-machine-suppliers/.

Where to Buy This Machine?

There are several sources. You could buy it off-line as well as online. Before placing the order, make sure you have finalized all the specifications. Don’t go to a store and ask them for recommendations. More often than not, you will get a recommendation for the machine which has the highest margin for the seller.

If you’re planning to buy online, make sure you ask for estimates from several sellers before finalizing one. Pay attention to their reputation, customer reviews and after sales service in addition to the above-mentioned factors.

Final Thoughts

Overall, the China charcoal machine is essential to convert rice husk into charcoal a commercial scale. There are several manufacturers of these machines but it’s important for you to carefully research several brands to get the best value for your money.