Sawdust is a great resource, and its value can be significantly multiplied when used correctly. Among all methods of recycling sawdust, creating charcoal from sawdust is certainly the most profitable. Since the material is not exactly the same in all places, the final result is often different. It’s excellent equipment for creating sawdust charcoal without oxygen.

Mostly, the sawdust charcoal making machine adopts the most advanced carbonization technology. What’s more, it’s environmentally friendly, and therefore, produces no harmful gases. Not only can the sawdust charcoal making machine process sawdust, but it can also process different types of municipal solid waste and biomass.

How Do You Make Charcoal from Sawdust? The Sawdust Charcoal Making Process

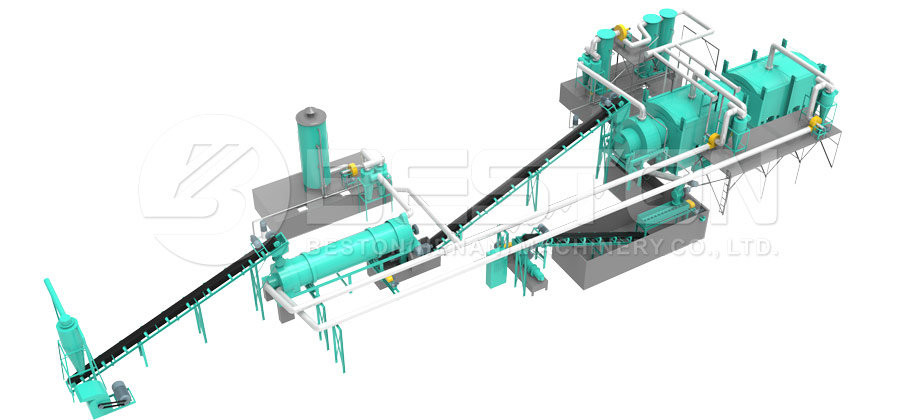

Typically, the charcoal making machine comes with a pretreatment system of raw material, drying system, raw material transfer system, cooling system for charcoal, carbonization system, exhaust gas purification and dust removal equipment, biomass gas collection system, wastewater purification equipment, and a collection system for wood vinegar and wood tar.

– For starters, sawdust or another biomass will be crushed to less than 50mm using a special shredder, which will then be sent into a drying machine using a quantitative machine.

– Dried sawdust is then sent into a carbonization furnace. After the cooling system cools the charcoal, it will be discharged.

– Using a sawdust charcoal briquette equipment, the charcoal can be turned into charcoal briquette. Furthermore, it can be reprocessed to form activated carbon. Click here to know more: https://bestonpyrolysisplant.com/.

Generally, sawdust charcoal is a form of renewable energy. Typically, the calorific value is considerably higher compared to ordinary charcoal. What’s more, it is clean, non-toxic, tasteless, and smoke-free. Charcoal is mainly used in three ways, including industry, agriculture, and daily life.

1. Daily life

– Charcoal is primarily used as a source of fuel for BBQ

– Also, it can be used as fuel in other areas

2. Industry

– It can be combined with clay to create bricks for construction

– When reprocessed, it can form activated carbon

– It’s primarily used as fuel in various industries, such as iron and steel factories, ceramics, etc.

3. Agriculture

– Since charcoal can actually absorb heavy metals, it can generally improve the soil quality.

The Pros of a Sawdust Charcoal Making Machine

– Environmental protection

As aforementioned, the sawdust charcoal manufacturing plant turns waste biomass into charcoal. Since the plant comes with a unique design, you will have the guarantee that the entire sawdust charcoal making process is absolutely pollution-free or environmentally friendly. In other words, there is no waste residue produced in the end.

– Security Design

The charcoal production equipment comes with an integrated PLC system. Typically, it’s possible to separate this system from the machine depending on the needs of customers. The recycled combustible gas is sent to the burner, and the burner often comes with a pressure gauge, an electronic ignition device, pressure relief valves, and an overpressure automatic alarm system. Lastly, the sealing system can make sure that the working environment is clean and safe for production. More relevant information on the page: https://bestonpyrolysisplant.com/wood-charcoal-making-machine/.