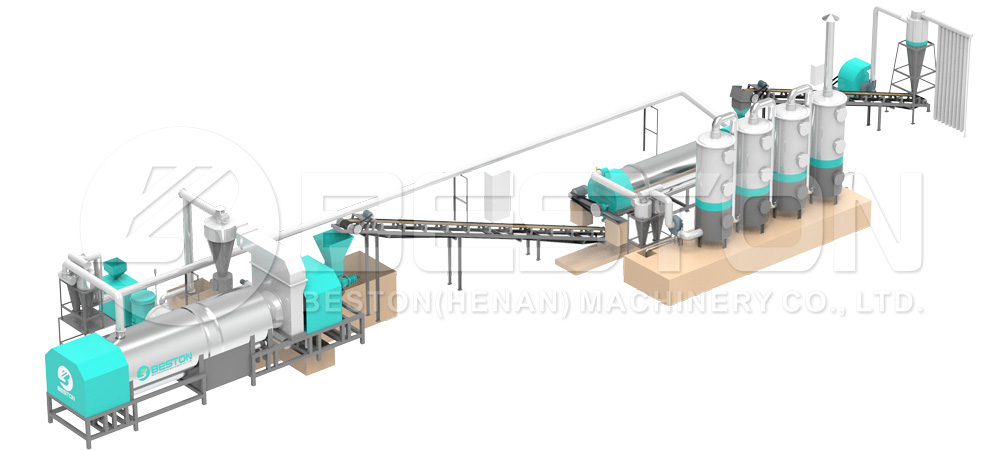

For most people, coconut shells are just another agricultural waste. However, for investors, these waste materials hold a lot of commercial value. Thanks to the coconut charcoal making machine, you can convert coconuts shells into coconut shell charcoal and other useful products. The coconut shell charcoal machine utilizes pyrolysis and carbonization to convert coconut shells into high-quality charcoal. This involves heating coconut shells under high temperatures in the absence of oxygen.

This is a significant improvement from the conventional methods of producing charcoal as it ensures the quick production of superior quality charcoal with minimal impact on the environment. These machines come with a dedusting and smoke purification system to minimize emissions.

End Products of the Coconut Charcoal Making Machine

It is important to note that coconut shells are not the only organic materials that the coconut charcoal machine can process. Other raw materials include wood, risk husks, bamboo, etc. This means that you are not limited by the choice of raw materials. The biomass carbonization plant is one of the most versatile machines.

Besides coconut shell charcoal, the other end products are wood vinegar, tar, and biogas – all of which have a significant commercial value.

Charcoal has a range of uses in different fields. It is commonly used for domestic and industrial heating purposes. It is also used in the agricultural sector to purify and improve the quality of the soil.

Tar is an important raw material in chemicals and medicine. It also has a demand in the paint and shipbuilding industry. In the agricultural sector, it is used to regulate auxin and in the production of pesticides.

Wood vinegar has powerful antibacterial properties. It is also used to condition soil. In addition, it is in the deodorant industry to neutralize sulfur and nitrogen compounds.

The biogas produced can be recycled and used to heat the furnace. It can also be collected and used as a fuel in industries and factories.

Types of Coconut Charcoal Making Machine

If you are looking to invest in a biochar kiln for sale, identifying the type you need for your job is crucial.

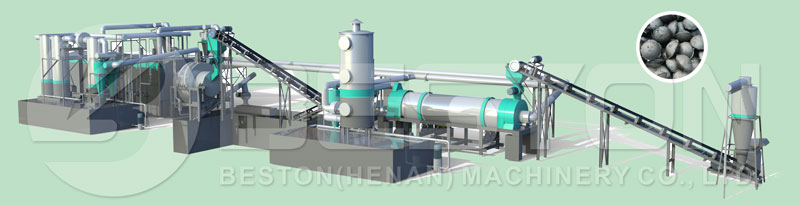

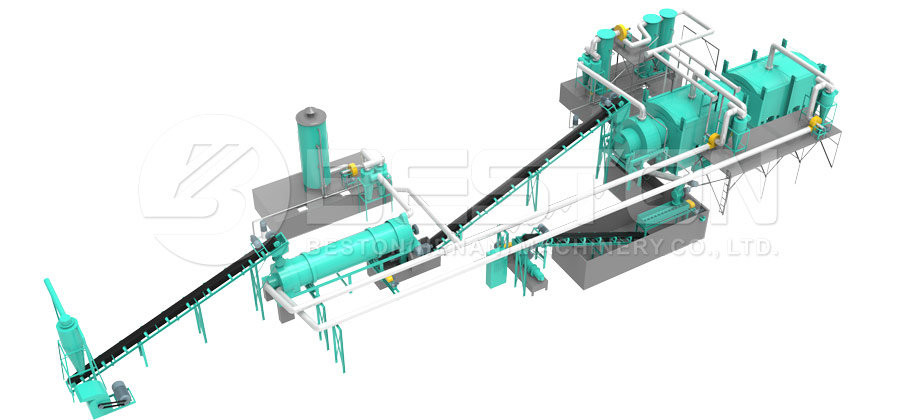

The coconut charcoal making machine comes in two types; batch and continuous coconut charcoal making machine.

The batch coconut charcoal making machine is the smaller version of the coconut charcoal machine. Depending on the model, it can process from 12-40 cubic meters of raw materials per hour. Given their small size and compact design, they are easier to transport and install. The batch coconut charcoal-making machine is ideal if you are running a small-scale operation or are limited on funds.

The continuous coconut charcoal making machine is designed for large-scale charcoal production. Depending on the model, it can process up to 5 tons of coconut shells per hour. It can produce large quantities of high-quality charcoal within a short period of time. In addition, it can work continuously for 24 hours straight. If you are looking to produce biomass charcoal on a large scale, then this is ideal for you. It comes as no surprise that this version is more expensive than the batch type. See some videos on this page https://bestonmachinery.com/charcoal-making-machine/videos/.