The tire to oil plant takes waste tires and turns them into fuel. This plant can recycle tons of tires and it prevents them from getting into the landfill which is very good for the environment. The plant is very efficient and it is also easy to use. It is a great investment and it can help you in a variety of ways. The plant is going to help save the environment and it is very easy to set up and use.

The plant can take any tire and quickly turn it into oil. This machine helps the environment and it ensures that waste gets taken out of the environment and gets transformed into something very useful. The pyrolysis oil plant helps you get a lot done and it can help ensure that the waste gets taken away and doesn’t end up in the landfill.

The waste tires are transformed into oil quickly and easily. The tires can produce a lot of oil and the oil doesn’t cost a lot to produce since the tires are inexpensive or even cheap. This machine is automatic so you don’t have to spend a lot of money on labor to run the machine.

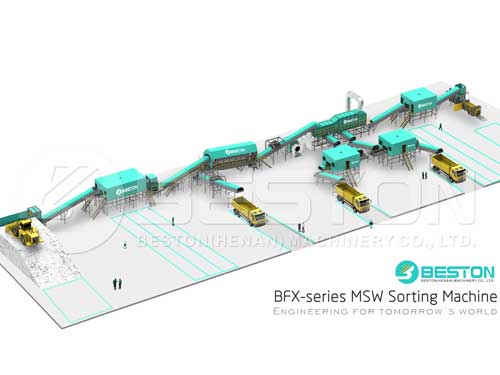

The machine is very cost efficient to run and it will run for a long time without experiencing problems. When you need a machine you can count on and you don’t want to spend a lot of time dealing with things that are difficult you need to ensure that you use this machine. You can find the best deals for the plant online, such as Beston Machinery, which will provide with the best tire pyrolysis plant cost. There are plenty of plants that you can choose from and there are a variety of models that are available that will help you get the most out of the machine.

This machine has a variety of features that makes it efficient and easy to work with. It doesn’t emit much pollution and it doesn’t cost a lot of money to run since the heating chamber is very efficient. The heating chamber has a special double layer that will ensure that the heat stays where it is supposed to be. The machine doesn’t get hot and will stay very cool to the touch even when it is in operation.

The machine can be controlled easily and it is also easy to program. Once the machine is programmed you can just let it run automatically and it will do what you need. Here is a video from Beston Youtube for you to learn the working process of tyre to oil plant.

The machine has many safety features that make it safe to operate and you don’t have to worry about problems when you use this machine. When you want a machine you can count on and that will make treasure out of trash, you want to find a tyre recycling machinery for sale. The tire to oil machine allows you to make a lot of money from waste tires and the machine will do everything you need it to do for an affordable price. When you need to get a lot of work done the tire to oil machine is a great investment.