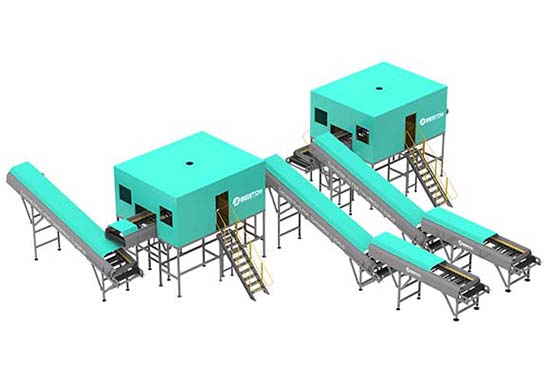

Producing egg trays is easy when you use a good egg carton machine. This machine allows you to create a lot of egg cartons in a short period of time. If you need to produce a lot of trays, you definitely have to invest in one of these machines since they allow you to produce a lot of egg trays quickly.

This paper egg carton making machine is a great investment in your business. It will help you produce a lot of trays quickly and you can easily create all of the trays you need with this machine. The machine allows you to create the trays fast and you won’t have to buy them from an outside vendor. You save money when you can create your own trays.

The trays are affordable and they help you save a lot of money. The trays are going to be what you need when you have to pack eggs and other things. The trays are affordable and they are strong. When you are planning on buying a tray machine you need to think about how many trays you are actually going to need for your business.

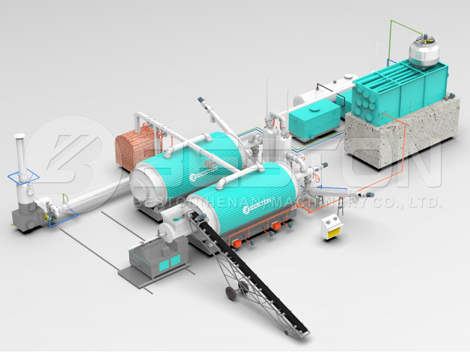

This machine can produce a lot of trays, but you have to buy the machine that is the right size for your needs. You need to do some research so you can easily find what you need. The machine comes in a variety of sizes. The machine can produce up to 6000 trays per minute if you buy the largest machine that is available. Click here to know more: https://eggtraymakingmachine.net/egg-tray-making-machine-manufacturers/.

The larger machines are going to be more expensive so you need to make sure that you choose the machine that is going to be the right price and will make the right amount of egg cartons. It won’t cost a lot of money to produce the egg cartons because they are made out of waste paper. You can produce a lot of cartons for a very cheap price and you won’t have to spend a lot of money on the paper.

The machine is easy to use and it is going to help you take care of all of your needs. You can easily take care of your egg carton needs with this machine and it won’t take a long time to learn how to use it. This machine is a great investment and it will help you take care of your work needs. You have a lot of choices so make sure that you choose the machine that is going to be the best choice. Making egg cartons is easy when you have the right tools for the job. See the blog: http://coses1957.doodlekit.com/.