Are you interested in investing in a biomass pyrolysis plant? If you’re looking at purchasing pyrolysis equipment, and you would like to find out more about the advantages biomass pyrolysis plant offers, you can read about some of the many benefits available to you below.

It Reduces Waste

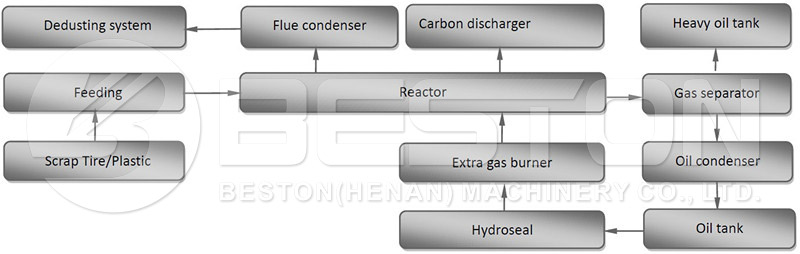

One of the biggest advantages of pyrolysis is that it’s highly effective at reducing waste. It is a highly effective way to convert many waste materials into usable goods. In fact, with pyrolysis, waste materials like rubber tires can be converted into materials that have high value, like oil.

Without pyrolysis, many of these materials would wind up in a landfill. With pyrolysis, it’s possible to continue to use these materials. It’s more important than ever to consider the amount of waste that we produce and to look for ways to reduce waste.

It Can Lower Emissions

Not only can pyrolysis reduce waste, but it’s also a highly effective way at reducing emissions. Pyrolysis equipment can have significant benefits from the environment. You may find that purchasing the right equipment allows you to lower your carbon footprint as well. Click here to know more: https://bestonpyrolysisplant.com/.

If you have concerns about the emissions that you’re producing, now is the ideal time for you to take action. Look into investing in equipment that will reduce the impact you are having on the environment. In some regions, purchasing this type of equipment could even entitle you to tax credits. Make sure you find out more about the options that are available to you.

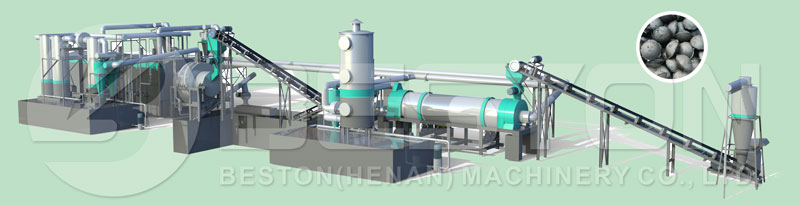

One major advantage of this technology is that there are many affordable options on the market. While the cost of pyrolysis equipment isn’t necessarily high, especially when compared against similar types of machinery, this technology is incredibly effective. It’s one of the best ways to recycle waste materials.

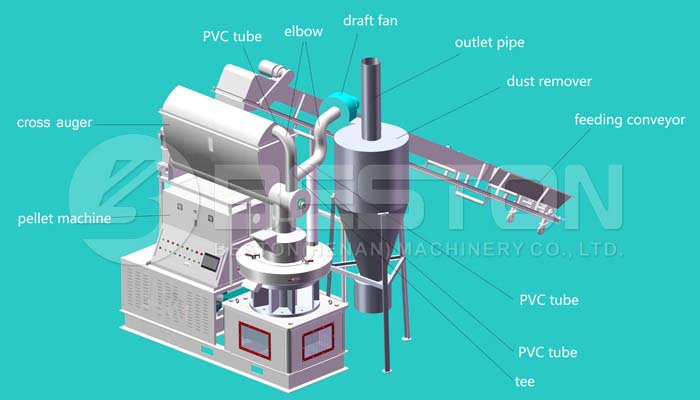

Pyrolysis equipment can provide an excellent return on investment, and the initial purchase price for this charcoal equipment can be very reasonable. If you do wind up investing in pyrolysis machinery, you can expect that the equipment you buy will do exactly what you need it to do.

Toxic Components Are Degraded At High Temperatures

Some of the materials that are recycled at pyrolysis plants contain toxic components. Because the temperatures used at these plants are so high, these components are degraded. Pyrolysis can ensure that these materials are no longer toxic.

It can be difficult to recycle some types of materials, but with pyrolysis, the process is much easier. Pyrolysis makes it possible to recycle these kinds of materials without causing damage to the environment around us. High temperatures can also cause pathogens to be degraded.

There are many excellent reasons to invest in a biomass pyrolysis plant. Take the time to find out more about some of the various options on the market and decide if this is an investment that you would like to make. No matter what your final decision is, you’ll be glad that you took the time to explore your different options. More information on https://bestonpyrolysisplant.com/sawdust-charcoal-making-machine/ here.