Cost optimization in tire pyrolysis systems begins with a rigorous assessment of preprocessing stages. Shredding, steel extraction, and rubber granulation are inherently energy-intensive. Minor improvements in machinery calibration can achieve significant savings. Short adjustments yield long-term benefits. Deploying low-friction cutting assemblies, high-torque motors, and automated feed controls reduces energy draw while maintaining throughput stability. Consistent particle sizing also improves the thermal uniformity inside a pyrolysis plant, preventing hot spots and elevating oil yield predictability.

Optimizing Thermal Conversion Dynamics

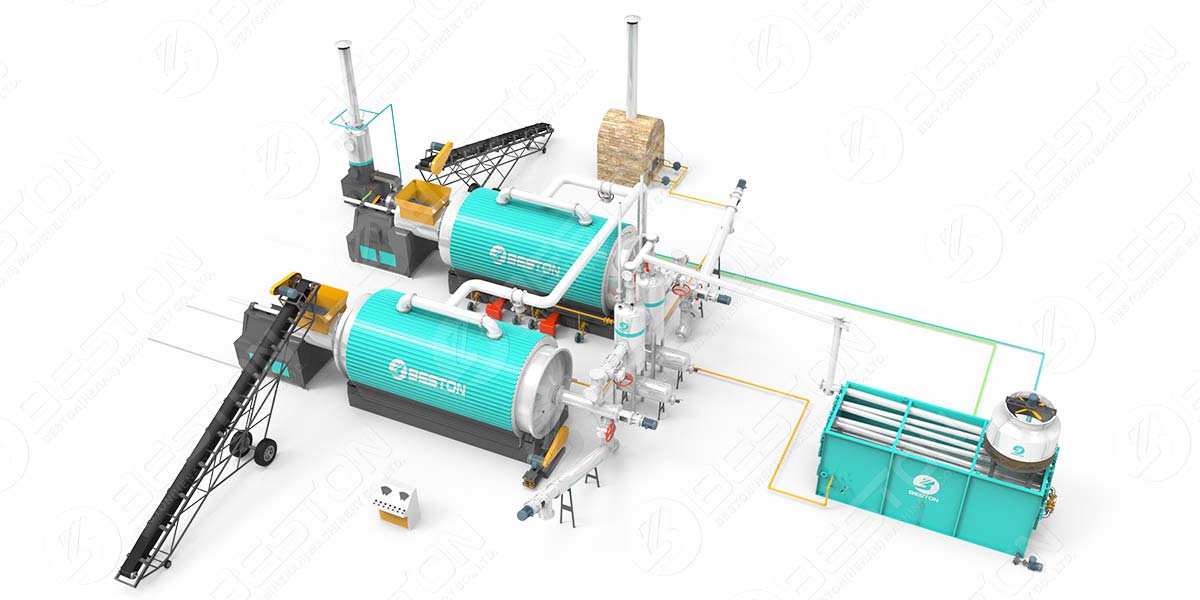

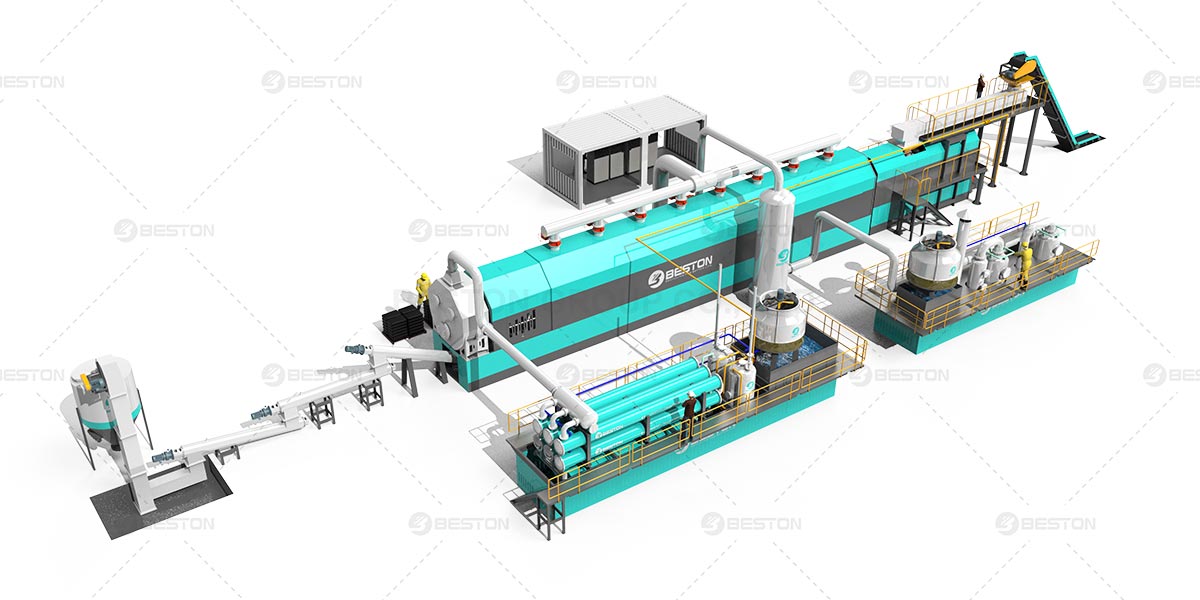

Thermal conversion accounts for a substantial share of operating expenditure. Efficient heat transfer, insulation integrity, and reactor geometry play critical roles in cost containment. A modern tyre pyrolysis plant benefits from advanced refractory linings with low thermal conductivity and high shock resistance. These materials curb heat loss and prolong component service life. Strategic recirculation of non-condensable gases back into the combustion chamber supplies a self-sustaining heat source. This greatly reduces external fuel consumption. When combined with high-accuracy control algorithms, the system achieves stable temperature regimes with minimal overshoot, further reducing energy waste.

Improving Condensation and Product Recovery

Oil recovery efficiency dictates revenue stability. Condensation modules should be engineered to maximize phase separation and reduce hydrocarbon losses. Multi-stage condensers, equipped with variable cooling circuits, are highly effective. They allow operators to tailor cooling gradients to specific tire-derived vapor fractions. Short sentences underscore precision. Properly engineered systems minimize clogging, reduce downtime, and preserve distillate quality. Higher purity pyro-oil boosts market value, thereby improving the financial performance of the entire operation.

Streamlining Carbon Black Processing

Carbon black derived from tire pyrolysis is an important revenue stream, yet its post-processing can become a major pyrolysis plant cost center if inefficient. Milling, pelletizing, and impurity removal require careful optimization. High-efficiency sieving units, abrasion-resistant conveyors, and dust-suppression modules significantly reduce handling losses. Chemical activation or micronization upgrades the market grade of the recovered char. While these enhancements require capital investment, they offer substantial long-term profitability by positioning the material for higher-value industrial applications.

Extending Equipment Longevity and Uptime

Maintenance strategies exert direct influence on cost optimization. Predictive maintenance tools—such as vibration analytics, thermal imaging, and real-time rotor diagnostics—enable early detection of system fatigue. Unplanned downtime is expensive. Strategic maintenance reduces repair frequency, boosts equipment lifespan, and stabilizes the cost of operations. In a well-engineered pyrolysis machine, modular reactor components and rapid-swap sealing systems further enhance uptime, especially in facilities processing high volumes of end-of-life tires.

Reducing Labor and Operational Overhead

Labor costs can escalate rapidly without a structured operations plan. Integrating supervisory control and data acquisition (SCADA) platforms minimizes manual intervention. Automated feed regulation, temperature adjustment, and safety monitoring decrease staffing requirements. Short statements remind us: automation reduces error. Enhanced situational awareness also supports data-driven decision-making, allowing management teams to adjust parameters in real time to maintain optimal cost-performance ratios.

Strengthening Supply Chain and Feedstock Economics

End-of-life tire sourcing represents another critical cost factor. Establishing long-term partnerships with tire collection centers, logistics firms, and municipal programs ensures a steady feedstock pipeline. Reduced procurement volatility stabilizes cash flow. Geographic clustering—locating the facility near concentrated waste streams—further reduces transport costs. Some operators employ reverse logistics models, leveraging existing distribution networks to minimize empty return trips. These strategies add structural resilience to the economic framework of the project. Looking for high ROI solutions? Contact Beston Group Co., Ltd..

Leveraging Byproduct Valorization Opportunities

Beyond pyro-oil and carbon black, tire pyrolysis generates steel wire and combustible gas. Steel separation can be enhanced using high-gradient magnetic systems that improve recovery purity. Clean steel commands higher resale value. Meanwhile, optimizing gas treatment expands opportunities for energy self-sufficiency or cogeneration. This integrated valorization approach offsets operational costs and elevates overall project economics. When engineered cohesively, each byproduct strengthens the project’s profitability profile.