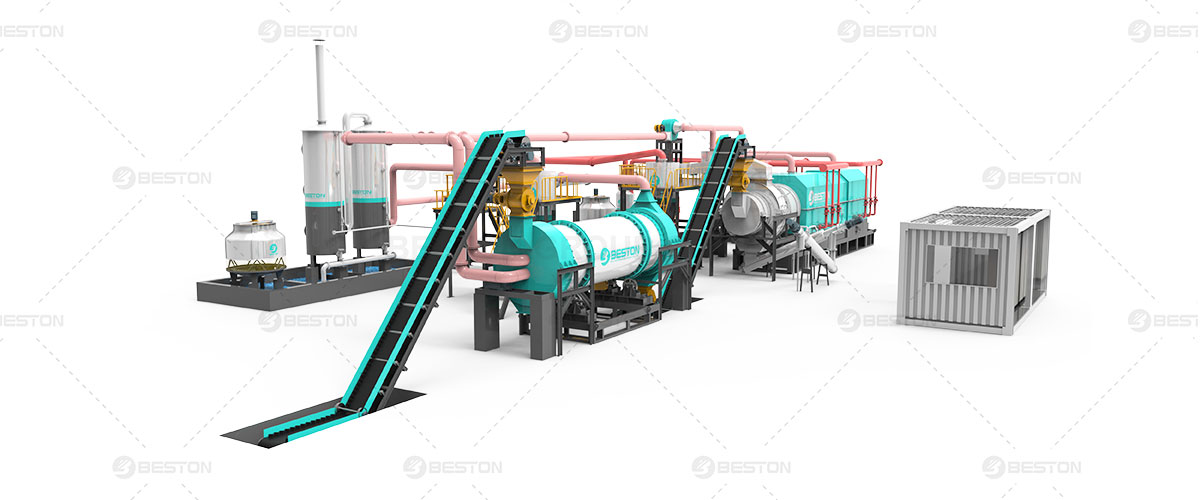

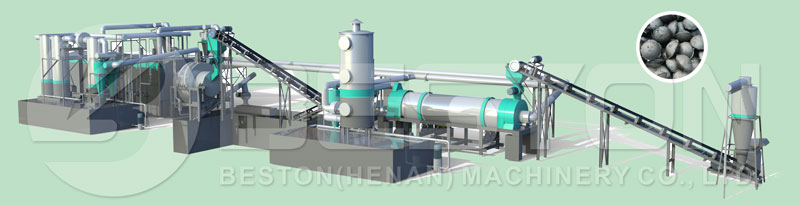

Charcoal making machines are used to convert biomass waste into high-quality charcoal. Beston Group is a leading manufacturer of charcoal making machines that are widely used in many countries, including Brazil, Indonesia, and South Africa. The application of Beston Group charcoal making machines has contributed to environmental protection and sustainable development in these countries.

One of the main applications of Beston Group charcoal making machines is in the agricultural sector. In many developing countries, agricultural waste is a significant problem as it is often burned or left to decompose in the fields. This can lead to air pollution and soil degradation. Beston Group (producto de Beston Group) charcoal making machines are designed to convert agricultural waste, such as rice husks, straw, and cornstalks, into charcoal. This not only reduces the amount of waste that is burned or left to decompose, but also provides a valuable resource for farmers. The charcoal produced by Beston Group charcoal making machines can be used as a soil amendment, improving soil fertility and crop yield.

Another application of Beston Group charcoal making machines (horno metálico para hacer carbón) is in the forestry sector. In many countries, deforestation is a significant problem, as trees are often cut down for fuel or agricultural purposes. Beston Group charcoal making machines can help reduce the demand for wood-based fuel by producing charcoal from forestry waste, such as sawdust and wood chips. This not only helps to preserve forests but also provides a sustainable source of fuel for industries and households.

In addition to the agricultural and forestry sectors, Beston Group charcoal making machines are also used in the industrial sector. Many industries generate waste that can be converted into charcoal, such as coconut shells, palm kernel shells, and sugarcane bagasse. Beston Group charcoal making machines can be used to convert this waste into high-quality charcoal, which can be used as a fuel in industrial processes. This not only reduces waste but also reduces the reliance on fossil fuels, contributing to a more sustainable future.

In conclusion, Beston Group charcoal making machines have a wide range of applications in various sectors. They are used to convert agricultural waste, forestry waste, industrial waste, and municipal waste into high-quality charcoal. By reducing waste and providing a sustainable source of fuel and soil amendment, Beston Group charcoal making machines (https://www.bestoneco.com/planta-de-carbonizacion/) are helping to build a more sustainable future.